A shed floor comprises three elements that should be considered in turn to give you a strong, durable and stable surface

The three elements of a shed floor, starting from the bottom up are:

- Floor supports - These are the beams or bearers that support the floor deck

- The floor deck is the flat structural surface that you walk on

- The floor covering is any finish that you apply to the deck. This can range from nothing at all, to some very expensive and upmarket flooring

Anyway lets look at each of the components in turn and see what you need to make a floor that works for you.

We'll start with the supports.

Shed floor supports

Shed floor supports fall into two categories bearers or joists.

Bearers are small section timbers that have limited spanning capacity. They are supported on a level surface such as a purpose built concrete shed base, level patio or timber sub-floor.

Floor joists are larger section timbers, generally 4x2 or 6x2 which span between supports and on to strip or pier foundations.

Both types of support work, the choice of which you opt for is partly personal preference, partly cost and partly what is already there where you are going to build your shed. Here are a few pointers to bear in mind with the two different schools of thought.

What is the difference between joists and bearers and why does it matter?

Floor joists are generally of a minimum size of 4x2" and support a floor by spanning at least a metre or more between supports. The supports to the floor would then be part of a shed foundation which could be a pad foundation or a foundation comprising timber bearers.

View of shed floor with joists

View of shed floor with joists

Floor bearers are an idea introduced by some shed companies to really minimise the material cost of the sheds they produce. The timber size is generally very small often 2x1" or sometimes less.

The bearer needs to have an almost continuous or very frequent support. The support could be a level concrete base or possibly a timber sub-floor.

View of underside of shed floor using bearers

View of underside of shed floor using bearers

Which is better, joists or bearers?

The short answer is it depends. ;-)

If you already have a level, flat foundation, such as a concrete shed base, then making a floor with bearers could well be the cheapest option. I would however still take measures to allow ventilation beneath the shed and to stop damp from the ground getting up into the floor.

View of timber 'sub-floor' to raise the bearers off the ground

View of timber 'sub-floor' to raise the bearers off the ground

If you don't have a ready-made foundation, constructing concrete pad foundations or a timber foundation will be cheaper and easier to build than a full blown concrete shed base. A pad or timber base is also easier to adapt later on if you need to extend the shed or remodel the garden.

There are a few common factors between joist and bearer supports and a few differences.

Three common factors between bearers and joists

1. Both types of support need to be pressure treated to increase their resistance to decay and insect damage.

Bearers are more likely to be in direct contact with the ground so may need to have class 4 pressure treatment. Alternatively bearers can be raised off the ground slightly by a sub-floor or another layer of impervious bearers. Both strategies will keep the timber drier and help the floor to last longer.

2. The supports for joists should incorporate some form of damp protection break.

This could be a layer of Damp Proof Course bitumen or PVC on top of a pad or using a screw jack to adjust the level and support a joist will lift it off the ground and stop it from remaining constantly wet.

View of underside of shed deck. The screw jacks support the floor joists and keep them out of contact with the ground

View of underside of shed deck. The screw jacks support the floor joists and keep them out of contact with the ground

3. The spacing of both joists and bearers will be governed by the type of structural floor decking that is used.

So typically I would work on 400mm centres for both types of support using 18-20mm thick decking.

Both types of support are timber and so fixing will be identical for both. The nail length should be 2.5 times the thickness of the flooring, so typically a 50mm nail will be used.

Three differences between bearers and joists

1. Joists are larger than bearers

Bearers are typically only 50mm deep so there is very limited space beneath the floor deck for ventilation and the floor is very close to the ground. Both factors mean that the floor deck can get damp.

The bearers on this floor provide minimal distance between the ground and the floor. Both will end up damp.

The bearers on this floor provide minimal distance between the ground and the floor. Both will end up damp.

2. Bearers need almost continual support

Joists only need support at intervals and span between pad supports. This allows free flow of air beneath the shed and keeps the supports out of the damp. It also means that insulation can be installed between the joists.

3. Joists are more versatile

Joists are sometimes used to create a level deck to support bearers for a shop bought shed. This is one of the best ways to stop a shed floor rotting.

The gap beneath the floor breaks the pathway for moisture from the ground and allows air flowing beneath the shed floor to dry out the timbers.

This timber sub-floor was built to lift the bearers off the ground and create a level surface on which to build the shed

This timber sub-floor was built to lift the bearers off the ground and create a level surface on which to build the shed

Shed Floor Deck

The deck is the flat surface that forms the wooden shed floor that you walk on. The material must be strong, able to span between the floor bearers/joists and be resistant to occasional damp.

The three most common materials used for shed floor decks are:

Timber tongue and grooved planks

Oriented Strand Board (OSB)

Plywood

Let's have a closer look at all three to see which material might suit your project:

1.0 The traditional flooring material is timber

Tongue and grooved planks are the traditional garden shed flooring. For durability they should be pressure treated to exposure class 3, this means they can resist occasional dampness.

The boards themselves will be a minimum of 20mm thick to span 400mm between joists. Also the edges will be a tongue and groove detail so that the boards lock into adjoining boards and don't deflect relative to each other.

Interlocking tongue and groove shed floor boards. A nail punch can be used to sink the nail heads below the surface of the floor

Interlocking tongue and groove shed floor boards. A nail punch can be used to sink the nail heads below the surface of the floor

2.0 Oriented Strand Board (OSB)

OSB looks like a load of wood chips stuck together with glue... and that is exactly what it is. However the chips are carefully sized and their direction controlled and the glue is water resistant.

I have written a lot more about OSB here to give you an understanding of the material.

When used for shed floors you need to make sure that you use a grade of the material classed as OSB3. This is made with a glue which is very resistant to moisture and damp.

OSB is generally available as 8x4 sheets which have a square edge. If you look you may find smaller sheets that have interlocking edges for use as flooring (at a higher price!).

To prevent differential movement between boards make sure that you have some sort of support along the board edges.

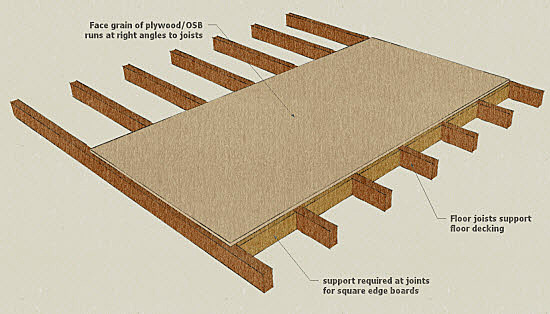

View of floor with plywood/OSB deck. Support to the edge of the 'sheet' is provided by timber 'noggins'

View of floor with plywood/OSB deck. Support to the edge of the 'sheet' is provided by timber 'noggins'

3.0 Plywood shed floor

The comments for plywood are very similar to that for OSB in the way that it is installed and fixed. There are many different types of plywood.

The one that I have used most commonly is shuttering ply. This type of ply has a rough face and a smooth face, so use the smooth face up.

Either way, make sure that the ply that you use is suitable for flooring in that it is resistant to damp.

A lot of people wonder which is better for a shed floor plywood or OSB?

For use as an outbuilding floor I don't see much difference between them structurally. The thickness of ply or OSB should, in my opinion be 19mm (3/4") with supports at 400mm (16") centres.

Many people try to use thinner material and close-up the centres of supports, but I think that this is a false economy.

In terms of appearance, plywood probably has the edge as people are used to seeing wooden floors and it could be thought more attractive.

For durability I don't think it could be possible to separate a good external plywood and OSB3. The more critical factor in terms of durability is to make sure that the floor doesn't stay permanently damp and it has good airflow beneath it.

The final floor component is the finish, the part that most people see and appreciate.

Shed Flooring Ideas

Many garden or storage shed floors will work just fine without a floor covering, whether they are timber planks, OSB or plywood. All are hard wearing and suitable for occasional use and storage type applications.

However many sheds are used for much more than utility purposes. Then you have a much wider choice of shed floor coverings.

If you just want to improve the general appearance then a coat of floor varnish or paint will seal the floor and make it much easier to maintain and keep the dust and dirt at bay. Also using mats in areas of high wear such as the entrance will protect the finish.

Other good options are lino and cushioned vinyl. These are both water proof and very easy to clean.

As for more upmarket floor finishes the sky is the limit. Many garden offices fit laminate floor or engineered timber boards down on top of the floor deck for a very high-quality appearance.

If you really want to make your shed cosy you could even use carpet. Though I think you would have to have strict rules about muddy boots and have somewhere to take them off at the entrance.

In summary :

There are three main sections to your shed floor:

The shed floor supports can be either joists or bearers. The choice of which is dependent on the type of support you want to use for your shed.

The floor decking material is the structural floor that is supported on the joists/bearers. It can be either timber planks, OSB or Plywood. All of these need to be resistant to occasional exposure to damp conditions.

The part that most people see is the shed floor covering. This may be the structural floor deck with our without a coat of paint or varnish. However the range of floor finishes that you can use is the same as for most domestic applications. I would always tend to focus on materials that are hardwearing rather than luxury.

Stuff in sheds tends to get more wear somehow than in the house.

Next step:

Related posts:

- Example of building a floor for a metal shed

- How to build a sub-floor for a timber shed

- The advantages of shed pier foundation

Keep in touch with our monthly newsletter

Shed Building Monthly