How to Choose Shed Door Hinges

The first thing to consider when choosing shed door hinges is are they for ornament or security?

I am only going to discuss normal utility hinges in here, but don't give up if you are interested in ornamental hinges. The same principles apply regarding strength and corrosion resistance however you will be paying more for a more bespoke item.

The majority of utility shed doors are of the board and batten type which don’t have a frame. Hinges for this type of door are of necessity surface mounted. As most shed doors open outwards the hinges are located on the outside of the shed.

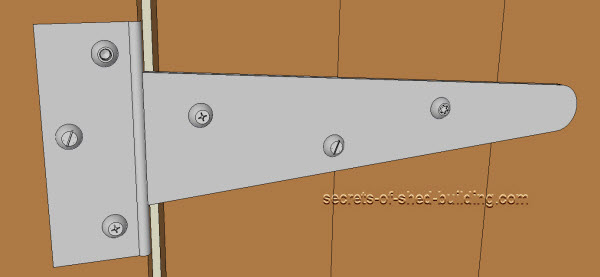

The most common type of shed hinge is the 'T' hinge. This has a short cross to the T for fixing to the door jamb and a long strap which fixes across the face of the door. The major problem with surface fixed hinges is that the fixings are exposed and accessible to potential intruders.

There are a few ways to make this type of hinge more intruder resistant. The simplest is to use screws with several different types of head. This would include a mixture of traditional slot headed screws, Philips screws and Torx screws. Using this strategy could slow down a thief but not stop an attempt to remove the hinge using a jemmy/crowbar. The crowbar would simply strip the threads out of the wood.

T Hinge fixed with 4 different type of screw heads

T Hinge fixed with 4 different type of screw heads

How to make the shed door hinges more secure?

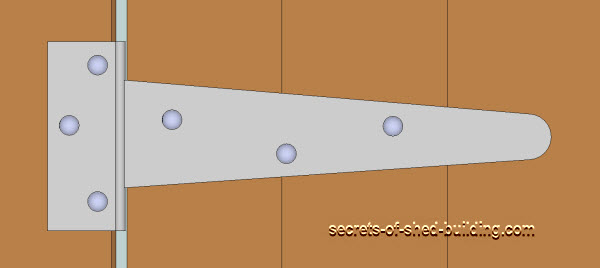

An improvement on security (and appearance) is to use a dome-headed coach bolt which passes through the hinge and the door ledger. The dome head cannot be turned with a screw driver. The nut and washer on the back of the door ledger/frame makes it almost impossible to use a crowbar to pull off the door hinge.

T Hinge fixed with dome headed coach bolts

T Hinge fixed with dome headed coach bolts

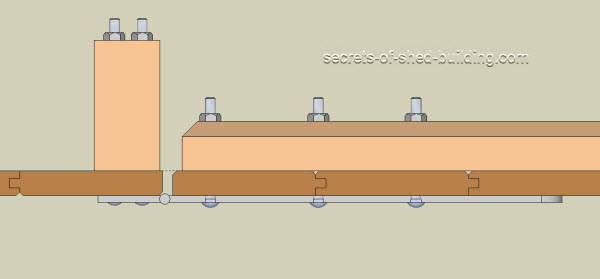

Section showing coach bolts passing through door frame and ledger

Section showing coach bolts passing through door frame and ledger

From this point, making the door more secure means choosing shed door hinges with thicker metal and larger holes so that you can fit a larger bolt. Typically a 3/8" or 8 mm diameter bolt is OK. From this point, you come up against the law of diminishing returns. It becomes easier for an intruder to break through the door than get an angle grinder to cut the hinge bolts.

We have looked at securing the hinge to the door

But what about the strength of the hinge itself?

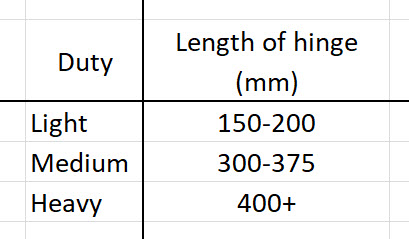

Shed door hinges come in a variety of lengths and material thickness. The table below gives the arbitrary strength grading and length from a typical hinge supplier.

Table showing manufacturers classification of T hinges

Table showing manufacturers classification of T hinges

Generally, a longer hinge made of thicker steel will support a heavier door. And bigger, stronger hinges are more resistant to unwanted attention.

An old carpenters rule of thumb for determining the required length of a T hinge is: 'One third of the width of the door and add 1 inch for every foot in height.'

So for a shed door that is 2'6" wide and 6' high then a hinge 16 inches (400mm) long would be needed.

In addition to the hinge material, inspect the hinge pin itself. Is it possible to drive the pin out with the aid of a screwdriver and a few blows of a hammer? If this is the case then it is easier for an intruder to remove the hinge pins and the whole door than attack the screws securing the hinge to the door.

The above points should give you some steer on selecting and fixing shed door hinges.

|

£7.50 (UK Only)

|

The next thing to consider is how to choose a long-lasting hinge?

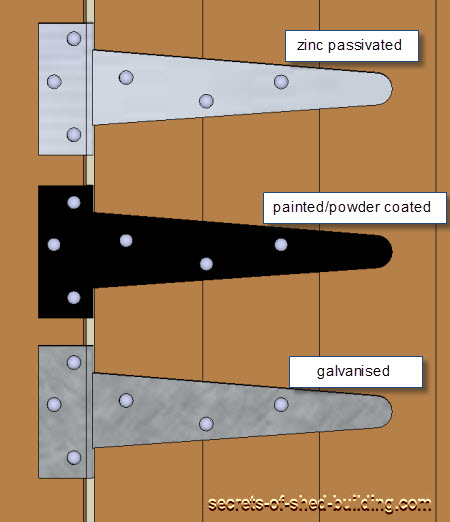

When you look in a hardware store you may find up to four varieties of T hinges made of different materials and with differing finishes.

Three of the hinges will be made of mild steel. Mild steel hinges typically come in one of three different protective coatings.

These coatings are;

- Zinc passivated. - Zinc passivated hinges look smoother and shinier than their galvanised equivalent. However they are only suited to indoor environments. They have less than 1/10 th of the protective coating of the galvanised hinge and will most likely start to rust in less than a year outside.

- Painted/powder coated (typically black). - The painted or powder coated hinges rely on the integrity of the coating to protect them from the onset of corrosion. If they are scratched or the coating damaged they can be repainted but the onset of corrosion is difficult to eliminate completely. This finish does look good on antique effect hinges, so can be used with care.

- Galvanised. - The king of finishes is galvanising. The item is dipped in a bath of hot zinc to give an irregular/rough but not unattractive silvery finish. The coating is 'self-healing', in that if the coating is scratched the zinc corrodes in preference to the steel beneath and forms a coating of zinc oxide that protects the surface beneath.

'Artists' representation of shed hinge finishes

'Artists' representation of shed hinge finishes

The importance of choosing the right coating shouldn't be understated. Replacing a hinge that has become covered in rust a couple of years after finishing your shed build is probably not worth the minor cost saving.

The cost difference between the zinc passivated and the powder coated hinges is about 10-15%.

The difference between the powder coated and the galvanised is another 10% or so.

As you might expect the more corrosion protection a hinge has the more it costs. Though in terms of expected lifespan it is probably worth it.

|

£11.25 (UK Only)

|

The fourth type is a stainless-steel shed door hinge

Shed door hinges made of stainless steel can be a fair bit more expensive than mild steel ones but there are some useful exceptions.

'T' hinges made of stainless steel are generally made for use in marine environments such as on boats. As such, there is a limited market for them and the prices are consequently up to 4 times higher than for their mild steel equivalent, if you can find them.

Stainless steel butt hinges

However, if you are fitting a standard framed door on your shed, using a stainless-steel ball bearing butt hinge could be a good move. These hinges are made in large quantities for external house doors and the prices are surprisingly reasonable. The hinges are made for heavy use over a long period of time and are designed to be exposed to the elements. The pictures below show one that I used on a summerhouse project.

Summerhouse with doors suitable for stainless steel butt hinges

Summerhouse with doors suitable for stainless steel butt hinges

Close up of stainless steel butt hinges

Close up of stainless steel butt hinges

Stainless steel parliament hinges

Another type of stainless-steel shed door hinge you might consider is a stainless-steel parliament hinge. Once again these are durable and designed for external use.

The benefit of a parliament hinge is that the point where the door rotates around is pushed outwards from the door frame. This means that the door can open through 180 degrees so that it can fit flush with the wall of the shed without conflicting with the door reveal.

View of stainless steel parliament hinge. As you can see from the picture on the right by selecting the right size length of projection of the hinge

the door can be enabled to clear the door reveal and fold back against the wall of the shed.

View of stainless steel parliament hinge. As you can see from the picture on the right by selecting the right size length of projection of the hinge

the door can be enabled to clear the door reveal and fold back against the wall of the shed.

Parliament hinges come in a variety of sizes, this enables you to choose the size of offset that you need so that the door can open and sit back parallel with the wall when it is open.

Heavy duty shed door hinges

The 'T' hinge is suitable for your average shed door but if you have some thing a bit heavier then you might consider the band and hook hinge.

This type of hinge is often used for gates and made from steel a lot thicker than your average 'T' hinge. In the picture below a shed door that was already fairly well constructed was over-clad in cedar to match the external shed cladding. This meant that the door was much heavier than normal and so these heavy-duty shed door hinges were used to effectively support the weight.

Inside and out of door requiring heavy duty shed door hinges

Inside and out of door requiring heavy duty shed door hinges

Similar hinges are used for heavy duty barn doors. The important thing when fixing these heavy-duty strap hinges are to locate them on the same line as the door ledge (the horizontal part) so that you are fixing through into something solid rather than just the face timbers of the door.

Plastic Shed Door Hinges

Plastic has made its way into everything that we use today, including shed door hinges. My experience of plastic shed door hinges is fairly limited but the ones that I have come across haven't worked really well. The ones on this summer house were less than a year old for example and the middle hinge had already cracked.

The hinges in the picture below looked a great idea. They wouldn't rust and they looked pretty much like the antique effect cast hinges. They were let down though by the fixings, which hadn't been selected for the resistance to corrosion. And also the strength of the hinge itself.

This plastic shed door hinge was less than a year old and had already become deformed.

This plastic shed door hinge was less than a year old and had already become deformed.

Plastic hinges may work for very light weight doors. Such as plastic doors on plastic sheds. However, for shed doors made of wood and also containing glass I would stick with metal hinges.

In summary

Shed door hinges are an important part of securing your shed. Appropriate selection of hinges and fixings can increase a doors resistance to unwanted attention.

Find out more about my range of hot-dip galvanised external quality shed hinges

Looking for more information on how to get your shed door working perfectly?

Return from shed door hinges to the Shed Door Hardware hub page

Keep in touch with our monthly newsletter

Shed Building Monthly