Frequently Asked Shed Siding Questions

by John Coupe

(Admin)

Shed Siding FAQ – I get asked a lot of questions about Shed Siding and so I have pulled these together onto one page for you to browse. Hopefully, you can find an answer to your question in amongst these.

If not please visit my Shed Questions page and ask away.

My only request before you do this is to take the time to submit several pictures and write a good summary your problem. I am keen to help but if I just get a one-liner saying - “I need some help with my shed roof!” it takes a lot longer to help you get to the root of the problem and find a solution.

I look forward to hearing from you if you don’t find an answer to your question below:

Return to Shed siding questions.

Leaking t&g boarding at the corners

by Allan

(Kent, UK)

My shed t&g siding just seep in water at one lower corner. It is on the weather side and I need to prevent any further water ingress. It must hold up against full sun and rain. Must also be easy to install and last the course. Hope you can help..

Answer:

Hi Allan,

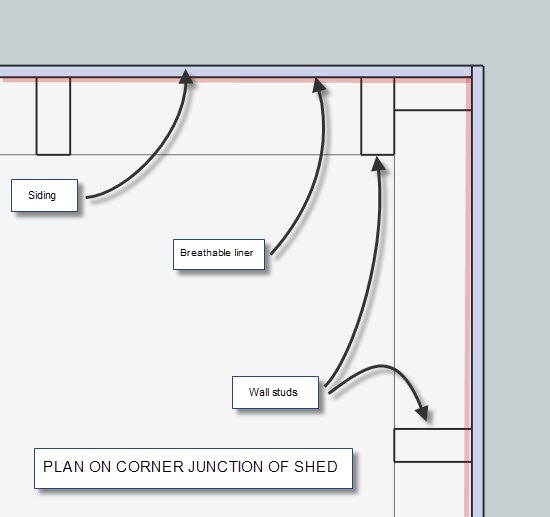

The typical detail that is used at corners is as shown below. This is fairly standard and so should prevent most wind-driven rain. The next level up from this would be to install a membrane as a second line of defence behind the t&g siding.

The membrane should be breathable so that water can escape from the building and is not trapped in little pockets. Which would cause localised rotting of timbers.

Hope this helps.

Regards

John

Return to Shed siding questions.

Shed siding

by Kevin

(PA, USA)

I'm building a simple 8'x10' storage shed. What are your thoughts on using Hardiboard(4'x8' sheets) that have the stucco appearance as opposed to standard T34 siding wood siding?

I'm also curious as to building an attractive but simple single door 42"-48" wide if I use the Hardiboard?

Thank you,

Kevin

Comments for Shed siding

|

||

|

||

|

||

Building Shed Walls - Question

by Ian Doherty

(Glasgow, Scotland )

Hi John, I'm building a shed this summer (can't wait!). I want to have a high-performance wall i.e. plywood sheathing, breathable membrane, cladding. Should I nail the cladding directly onto the breathable membrane or attach battens or firring strips for the cladding?

Answer:

Hi Ian,

Thanks for your question. You are right that you would nail timber strips on to the outside of the breathable membrane. The timber strips should be about 1 1/2" x 3/4" treated timber as they will in a damp environment. The purpose of spacing the cladding off the wall is to allow air flow behind the cladding timber and stop the accumulation of moisture which would occur if the timber cladding was nailed directly to the membrane. Also, remember to put wire mesh insect screen at the bottom to prevent insects getting into the void.

Best of luck with your project, let us know how you get on and of course feel free to ask any more questions as you go along.

Cheers

John

Return to Shed siding questions.

Vinyl siding

by Robert

(United States)

When building a vinyl sided lean-to shed against a vinyl sided garage wall, how do you attach the shed roof to the wall so no water goes between the garage and shed and what do you do about the gaps along the attached walls?

Thanks!

Comments for Vinyl siding

|

||

|

||

Using decking boards as shed siding

by John R

(UK)

Using Decking Boards instead of T&G or Feather edge timber

We are considering using decking boards to make our shed - is there an issue with this? Have scoured the Internet for advice but the can only find info for Tongue and Groove and feather edge boards.

Also, my husband is planning to fix them vertically, rather than horizontally; is there a reason timber tends to be fixed horizontally?

Answer:

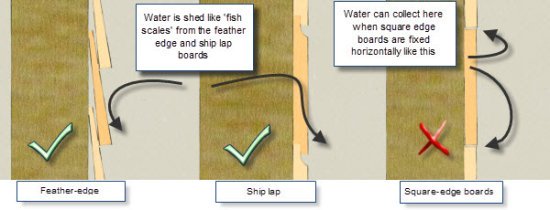

The sketch below should answer the first part of your question. The purpose of the profile of feather-edge, shiplap and tongue + groove cladding is to act like overlapping fish scales and not allow water to accumulate on the outside of the shed. As you can see from the right-hand image when square edged boards are fixed horizontally the provide a ledge where water and moisture can stay. This eventually will lead to the boards decaying.

For the second part of your question. There is no reason why the boards shouldn’t run vertically. In contrast to the first part of the question. When the board run vertically there is nowhere for rainwater to collect. This is good.

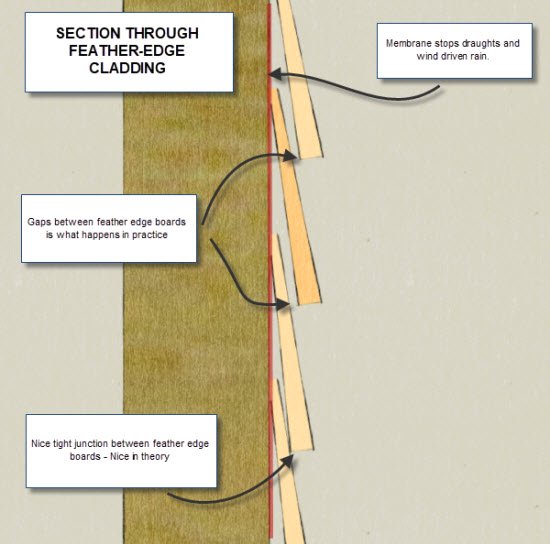

The gaps between the boards need to be waterproofed in some way. This could be a timber batten nailed on top of the gap between the boards to block wind-driven rain. Or it could a breathable membrane behind the cladding line, as on the image below.

Most commercial sheds have horizontal cladding for the simple reason that the main structural components of the shed wall run vertically. The easiest and cheapest, way to fix cladding is to run it horizontally. However, if you are building your own shed and already have the decking boards then fixing some noggins between the studs to enable you to get the effect you want will only take a small amount of extra time and the cost will be tiny in the scale of the project.

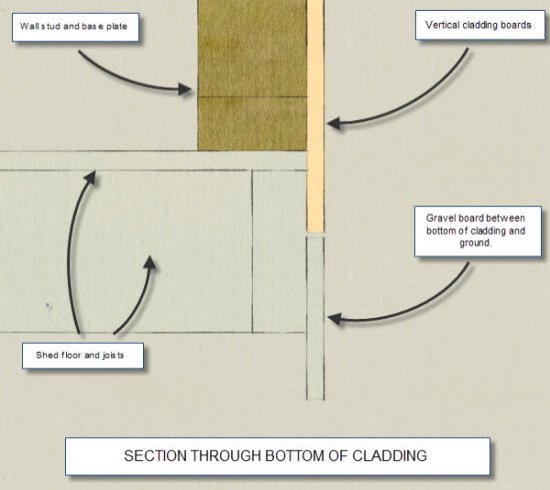

One detail to be aware of is the detail at the bottom of the shed wall. The vertical board should overlap the floor to keep this area waterproof. But stop the boards short of the ground and use a ‘gravel board’ to fill the gap between the ground and the bottom of the boards. The reason for this is that the internal structure of timber is like a bundle of tubes. If this is in contact with the ground or near the ground it will ‘wick’ up and hold water. Over time this will initiate rot in the bottom of the cladding. The way I have shown is to have a horizontal gravel board which can be replaced every so often, just like a cars tyres.

I hope that this helps.

Regards

John

Return to Shed siding questions.

sheathing and vinyl siding starting location

by Dave

(New Jersey)

I understand that the vinyl siding will cover the sheathing and come down as far as the sheathing on the sill plate. Can you tell me how far down the sheathing should come down on the bottom sill plate? Can I just start the sheathing where the bottom plate is or do I need to cover the sill plate or at least some of the sill plate with the sheathing and the vinyl siding?

I am building a shed and I want to have 8-foot walls. I could not find any plans for a shed with 8-foot walls and vinyl siding so I am modifying the plans that I found for a 7-foot shed with t111 wood siding. I am using 2 x 6 pressure treated sill plates and I am trying to determine where to start the sheathing. Since the sheathing comes in 4' x 8' panels if I start the sheathing over the sill plate then should I cut a small piece of sheathing to compensate for the lowering of the full panel on the sill plate? If so where should I install the small piece of sheathing?

Answer: From John - Admin

Hi Dave,

Thanks for your question.

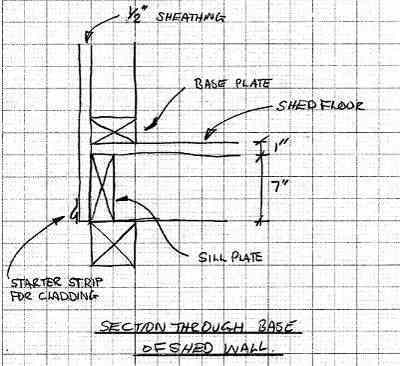

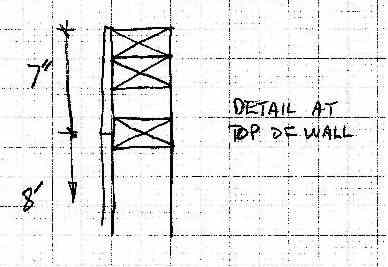

I think that a picture is worth a thousand words so I hope that the sketch below answers your question. The sheathing should be continued over base plate and the sill plate. This protects the sill plate from water and sunlight for long-term durability. The vinyl siding will be started with a starter strip or a starter strip and metal flashing (dependant upon the system that you use) right at the bottom of the sheathing. Make sure that the bottom edge of the sheathing is protected as this is an area that water can collect and rot the sheathing if not installed as per the system specification.

With respect to the wall height, with this arrangement, you will get a wall height of 7’ 5” using the standard 8’ sheet. If it is absolutely critical that you achieve the 8’ wall height then you will need to have some 7” strips at the top. The joint between the two sections of sheathing should be backed by some noggins as shown on my second sketch to provide some support to the sheathing.

Let me know how you get on, more questions welcome as usual and progress photos are always welcome.

Regards

John ;-)

Comments for sheathing and vinyl siding starting location

|

||

|

||

To use a shed lining membrane or not?

by Brian W

(Berkshire, England)

I am designing a shed (5m x 3.5m) which I am going to use feather edge boards on. So the question is.... should I lay a weatherproof layer over the stud wall before applying the feather edge? If so can I use polythene sheet or should I use a breathable membrane? The shed is for general use but I want it to be waterproof. Your thoughts are most welcomed.

Answer:

Hi Brian,

I would definitely use a breathable membrane.

When using feather edge boards there is no ‘interlock’ between the boards such as you get with shiplap or matchboard. This means that if (when) the boards warp that an air gap will be created between them. Making the inside of the shed draughty. The membrane behind the boards will significantly reduce the draughts and air loss from the shed.

It is important to have a breathable membrane. A non-breathable membrane such as polythene will allow moisture to build up inside the shed making the inside unnecessarily humid. Also, any moisture trapped between the polythene and the timber would cause localised rotting of the timber.

The membrane is secured by stapling it to the timber stud frame before nailing the boards in position.

Cheers

John

Return to Shed siding questions.

Shed Wall Security

by Ben Ellis

(suffolk UK)

I am currently planning a big build after years of messing with small sheds. I am building a shed for storage of a very expensive quad bike with several snap on tool boxes and music equipment. I was just trying to find out your opinion on my wall structures.

To make it secure from thieves I was going to line the outside of the shed with ship lap then insulation with a steel checkerplate finish on the inside as thieves in Suffolk have been cutting through shiplap and stealing goods. I know this won't stop them breaking in but will create enough noise to at least get noticed. I would like to hear if you like the idea or possibly have a better idea.

Many thanks

Ben Ellis

Comments for Shed Wall Security

|

||

|

||

|

||

Keep in touch with our monthly newsletter

Shed Building Monthly