How to design shed roof insulation without creating condensation problems

Installing shed roof insulation seems straight forward to start with. You are building a new shed and would like to be able to use it in the colder winter months. You decide that you need to heat the shed to keep you and the contents warm and so to minimise the heat loss and keep the heating bills down you correctly decide that you need to insulate it.

All good so far, but the devil is in the detail. What are the problems commonly encountered with shed roof insulation and how can they be avoided?

The main problem encountered with flat roofs is condensation. Warm, moist air generated by the room's occupants rises to the roof. When it meets the cold underside of the roof it condenses as liquid water (more on this here). In the short term this dampness can damage finishes, causing staining. In the longer term the dampness can initiate mould, fungal growth and decay of the roof deck and timbers.

There are two common strategies used to avoid the problems of condensation in flat roofs; these are the warm roof and the cold roof.

There is also a third option which is of great benefit in certain situations, the hybrid roof.

Let's look at cold roofs to start with

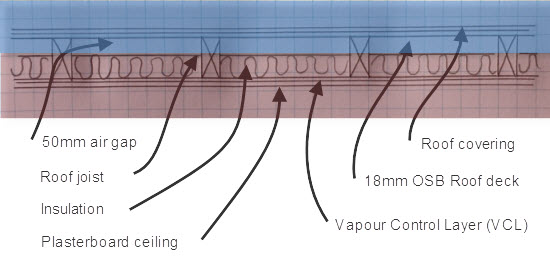

Cold roofs are termed 'cold' as the roof joists and deck are above the insulation and so cooler than the internal room temperature. The picture below demonstrates a typical cold roof detail.

Section through a 'Cold Roof' showing the principal elements

Section through a 'Cold Roof' showing the principal elements

As you can see the shed roof insulation is fitted between the roof rafters, there is a minimum of 50mm air gap required above the top of the insulation and the underside of the roof deck. The purpose of this air gap is to allow any moisture that gets into this void to escape. Vents are required in the eaves at each end of the roof to allow this.

Below the joists there is a Vapour Control Layer (VCL) which is designed to stop any of the warm moisture laden air at ceiling level getting through and into the roof void. The plasterboard roof finish is applied beneath the VCL.

The problems with cold roofs occur when insufficient cross ventilation is achieved. And also, when holes in the VCL for downlighters or other reasons allow moist air into the ventilation void and it condenses.

The cold roof is a useful solution but a better way exists.

The warm roof is a better shed roof insulation solution than the cold roof

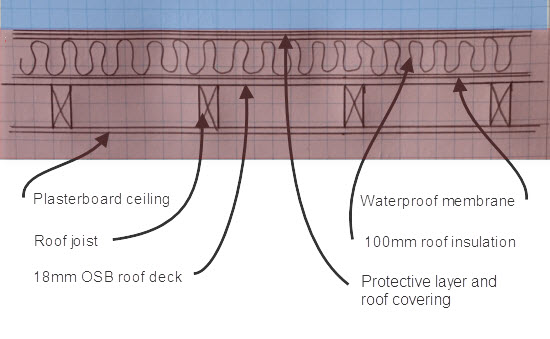

As you can see in the picture below, the shed roof insulation is located above the roof deck.

Section through a 'Warm Roof' showing the principal elements

Section through a 'Warm Roof' showing the principal elements

This has a major advantage as both the roof deck and joists are located on the warm side of the insulation. They are both therefore warm and so not prone to water from the warm moist air condensing on them. Hooray!

In many situations this would be the optimum situation and in an ideal world this would be the preferred solution.

However, the fly in this ointment is that we have two conflicting requirements.

The first is that in the UK most buildings constructed in back gardens under 'permitted development' rules have a maximum building height of 2.5m. This is an external limit.

Secondly there is the understandable desire to achieve a usable room height in the garden building. This is an internal limit.

To see how these two limits create conflict lets see what the typical height of a garden building works out.

A typical garden building height make up to comply with the 'Permitted Development' height restriction is as below

Starting at the roof and working down:

- 20mm plastic upstand

- 1mm rubber

- 18mm OSB roof deck

- 120mm 5x2 roof joist

- 160 deep joist over door

- Opening for door 1965mm (door 1950mm)

- 22mm Egger protect floor system

- 100mm floor joist

Total of items 1-8 = 2406mm

This allows for clearance beneath shed for airflow to keep the base and floor dry.

The conflict arises as follows

Given these fixed dimensions, adding 100mm on top of the roof would exceed the permitted development height. So, the warm roof in this situation wouldn't be acceptable.

If you were to revert to the cold shed roof insulation solution, in order to achieve the desired 100mm of insulation then you could only fit 70mm of insulation between the joists to give the required 50mm airflow gap for ventilation. So, an extra 30mm of insulation would be required beneath the joists which would impinge on the room height.

What is the best way to solve this situation?

The hybrid roof insulation system is a third way to insulate the roof

The hybrid shed roof insulation system works as in the sketch below.

Section through a 'Hybrid Roof' showing the principal elements

Section through a 'Hybrid Roof' showing the principal elements

As you can see, in contrast to the cold roof, the insulation is pushed up hard against the underside of the roof deck. The vapour control layer is directly below the joists and above the plasterboard ceiling.

Critics of this shed roof insulation system point to the 20mm void beneath the insulation, which is less than the minimum required for ventilation. However the air in this space is likely to be dry and all of the surfaces where condensation could occur are warm.

This solution isn't ideal and has its critics, as many hybrid systems do. But to my mind it works and achieves its aim of staying within permitted height limits whilst also keeping the room height intact.

The success of the system lies in the understanding that garden offices are not High Occupancy rooms. They don't get a high number of people and consequently a high humidity level. Also, in contrast to two storey domestic buildings they only have one level and so the amount of moisture laden warm air rising to the roof is less. In addition, garden offices don't generally have two of the highest generators of damp warm air - kitchens and bathrooms.

The upshot is the likelihood of condensation on a well-constructed and insulated garden room roof is less than an equivalent domestic building.

This system has been used successfully in many garden offices. As long as you understand the limitations of the system and don't overload it with moisture it should give a very good outcome.

A conclusion on shed roof insulation

The main problems with flat roofs occur due to warm air from the interior of the building condensing on cold roof surfaces.

It is possible to avoid condensation using either a warm or a cold shed roof insulation system. Both of these systems are tried and tested. However, when it comes to their use in a flat roofed garden building they can lead to problems with height on the inside or outside of the building.

To overcome the dimensional issues a 'hybrid' system can be used which combines elements of the cold and warm roof.

Keep in touch with our monthly newsletter

Shed Building Monthly