Garage/Workshop Foundation Detail

by Dan

(Spalding, UK)

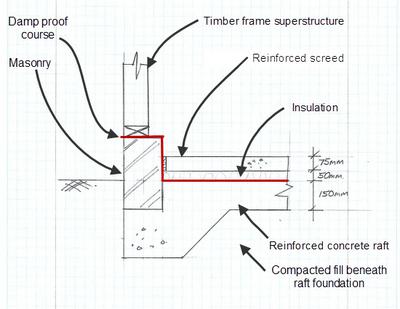

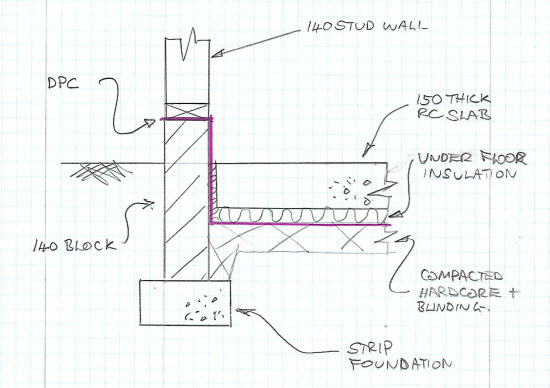

I'm looking to build a garage workshop 6.5 x 7.5 x 3.2/4m. My slab will be 150 -200mm steel reinforced with 50mm of Celotex under it. My question is, what do I do with the DPM at the edges? Should trim it down and have a gravel moat around the building or I could bring it up the side of the slab and hold it down with the sole plate (or even up the framing and pin it under the cladding?? I was going to lay a strip of doc under the plate anyway.

I'd love to hear your thoughts.

Dan

Answer